It is also less likely to catch fire and has a lower environmental footprint.

It’s easier to imagine our day with lithium-ion battery power. These batteries are used extensively in electric vehicles and the small-format battery market for electronic devices. However, there are severe problems with lithium-ion batteries, such as potential fire hazards, performance loss at low temperatures, and the environmental impact of spent batteries disposal.

Oleg Levin, a Professor at the Department of Electrochemistry at Petersburg University, heads the research team. He said that the researchers have been investigating redox-active, nitroxyl-containing chemists as materials for electrochemical energy storage. Due to their fast redox kinetics, these polymers have a high energy density and fast charging and discharging speeds. Low electrical conductivity is a problem in implementing such a technology. Even with highly conductive additives like carbon, this hinders charge collection.

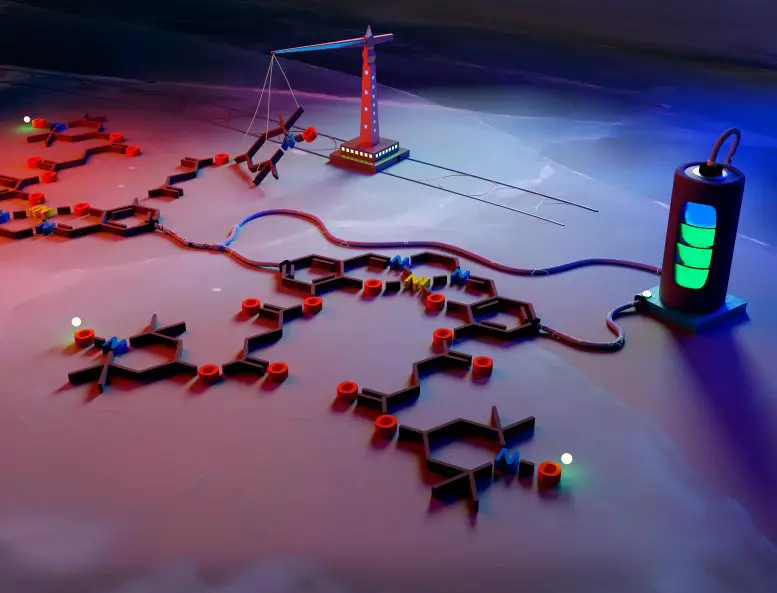

St Petersburg University researchers developed a polymer based on the nickel-salen compound (NiSalen) to solve this problem. This metallopolymer acts as a molecular wire that can be attached to energy-intensive nitroxyl pendants. High capacitance can be achieved at a wide temperature range due to the molecular structure of this material.

In 2016, we came up with the idea of this material. In 2016, we came up with the idea of this material. We began developing a project called “Electrode materials to lithium-ion battery based on organometallic polymers.” The Russian Science Foundation granted a grant to support the project. We discovered two critical directions for development when studying the charge transport mechanism of this class of compounds. These compounds can protect the main conductor cable of a battery otherwise made from traditional lithium-ion batteries materials. Oleg Levin explains that they can also be used as active components in electrochemical energy storage materials.

It took three years to create the polymer. The scientists developed the polymer concept in the first year. They combined components to create an electrically conducting backbone. Ensuring that the structure worked together and supported each other was crucial. Next came chemical synthesis. This was the most challenging part of the project. Because some components are susceptible, even the slightest error by scientists could cause the degradation of samples.

Only one of the many polymer samples was stable enough and efficient. Complexes of nickel and salen ligands form the main chain of this new compound. Covalent bonds have been used to link the main chain with a stable free radical capable of rapid reduction and oxidation (charge and discharge)

“A battery made with our polymer can charge in seconds, about ten times faster than a traditional lithium-ion. Through a series of experiments, this has been proven. It is still far behind lithium-ion batteries in capacity, ranging between 30-40% lower. Oleg Levin says we are improving this indicator and maintaining the charge-discharge rates.

The new battery’s cathode has been made – an upbeat electro for chemical current sources. The anode, or the negative electrode, is now needed. It doesn’t have to be made from scratch. You can choose from existing ones. They will create a system that may soon replace lithium-ion batteries in certain areas.

“The new battery can operate at low temperatures, making it an ideal option for fast charging. It can be used safely, as there are no hazards to combustion. This is in contrast to a cobalt-based battery that is widely available today. It contains far fewer metals that could cause environmental damage. Oleg Levin says that although nickel is found in some of our polymers, it is less than in lithium-ion batteries.