KAIST researchers developed a new nanofiber production method called ‘centrifugalmultispinning,’ which will allow for safe, cost-effective mass production of high-performance polymer Nanofibers. This new technique has a 300-fold higher nanofiber production rate than the traditional electrospinning method. It has potential applications, including developing and manufacturing coronavirus protection face mask filters.

Because of their mechanical interactions with aerosol particles, nanofibers are better to face mask filters than other types. They can capture more harmful particles like fine dust and viruses-containing droplets.

Recently, the demand for a superior face mask has increased due to the COVID-19 outbreak. As the pandemic continues, a polymer nanofiber-based face mask filter that blocks harmful particles more effectively has been in high demand.

Although electrospinning is a standard method for producing uniform and fine polymer nanofibers, it has some drawbacks regarding safety, cost-effectiveness, mass production, and safety. The electrospinning process requires an electrically conductive target and a high-voltage electric field. This makes it challenging to mass-produce polymer nanofibers safely and economically.

To solve this problem, “centrifugal spin” has been proposed as an alternative to electrospinning. It uses centrifugal force rather than high voltage to make polymer nanofibers. This technology is easy to scale since it only requires a spinning spinneret and a collector.

The existing centrifugal force-based spin technology uses only one rotating spinneret. This limits productivity and makes it less productive than other advanced electrospinning technologies like multi-nozzle electricspinning’ or ‘electronic nozzle spinning.

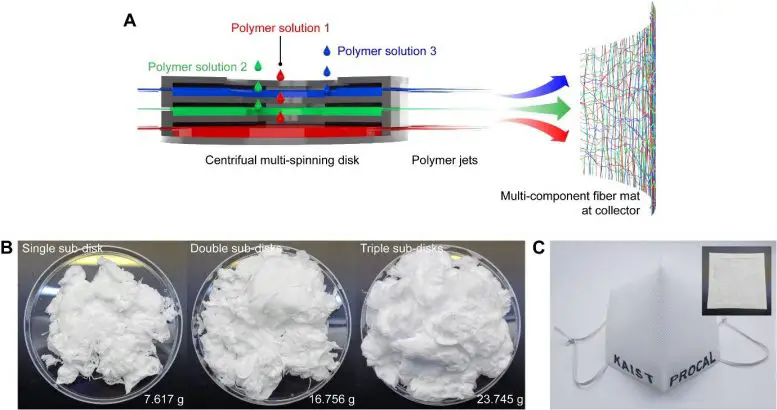

These limitations inspired a research team headed by Professor Do Hyun Kim of the Department of Chemical and Biomolecular Engineering, KAIST, to develop a centrifugal multispanning spinning spinneret that is mass-producible by dividing a rotating spinneret into three sub-disks. This article was published in ACS Macro Letters Volume 10, Issue 3, March 2021.

KAIST researchers developed a new nanofiber production method called ‘centrifugalmultispinning,’ which will allow for safe, cost-effective mass production of high-performance polymer Nanofibers. This new technique has a 300-fold higher nanofiber production rate than the traditional electrospinning method. It has potential applications, including developing and manufacturing coronavirus protection face mask filters. Credit: Professor Do Hyun Kim, KAIST

The paper’s lead author, Ph.D. candidate Byeong Eun Kuk, and his co-researchers Hyo Jeong Yoo, and Eungjun Lee, demonstrated the gram-scale production and processing of polymer nanofibers using a new centrifugal multispanning spinneret that has three sub-disks. This is 300 times more than the traditional electrospinning system. This is equivalent to about 30 face mask filters per day in a laboratory-scale manufacturing process.

Researchers created mask filters that combine the mass-produced polymer nanofibers with a mask filter. They have similar filtration performance to the KF80 or KF94 masks currently on the Korean market. The Ministry of Food and Drug Safety of Korea has approved the KF80 and KF94 covers to filter out at most 80% and 94% of harmful particles, respectively.

Kwak stated, “when our system is scaled from the laboratory scale to an industrial level, the large-scale manufacturing of centrifugal multi-spun, polymer nanofiber-based face filters will be possible.”